Kohler Engines showcased its latest 2012 version of KD441 engine at the 11th New Delhi Auto Expo on 5th January 2012. This USD 5 billion company is a part of the Kohler Co. and is head quartered at Wisconsin, U.S. The new engine unveiled at the auto expo has improved power, torque and fuel efficiency than the earlier version. Besides this new engine, the company also displayed other engines for the ‘last mile connectivity’ vehicles. The company has been engaged in developing technology that emphasizes on better combustion, which leads to better fuel efficiency and lower emission.

Talking about this, Sudipto Mukherjee, GM Marketing, Kohler Engines Division of India commented that “I take immense pride to announce that Kohler Engines Division in India has successful achieved BS-IV emission norms with the single cylinder air cooled mechanical engine – KD441 in the Indian Automotive Market, the first of its kind in the world to fulfill Stage-IV norms. The trials for the same are going on vehicles of few leading Indian automakers and the certification formalities will be completed in due course. Kohler Engines is now ready to offer engines for 700-800kg and 900-1,000kg payload 4-wheel commercial diesel vehicles – Mechanical engines for BS-III and Common Rail versions of same engines for BS-IV.”

Kohler Engines provides comprehensive range of engines, with a payload of up to 1.0 Ton. It has emerged as the undisputed leader in the country for engines for 500kg payload 4-wheel commercial diesel vehicles. Some of the vehicles which are equipped with the Kohler KD441 engine are Piaggio’s Ape Mini (Goods Carrier) and Mahindra & Mahindra’s GiO (both Goods and Passenger Carrier). This direct injection, 9.2 hp/6.8kW single cylinder engine boasts of 441cc displacement and fuel economy of 27+kmpl.

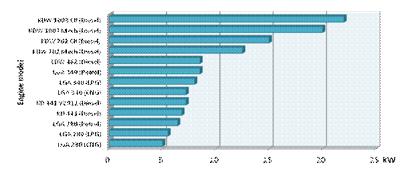

The 2-cylinder, 686cc, water cooled, 12.5kW KDW 702 engine has been chosen as an ideal solution for meeting the BS-III emission norms. For the 700-800kg payload vehicle segment, it offers a perfect balance between power and fuel economy. Furthermore, the engine’s common rail version, which is complaint with the BS-IV emission norms, is capable of producing 15.0kW power.

The 3-cylinder, 1028cc, water cooled 20.0kW KDW 1003 engine also meets the BS-III emission norms. For the 900-1,000kg payload vehicle segment, the engine offers a perfect balance between power and fuel economy. Furthermore, the engine’s common rail version, which is complaint with the BS-IV emission norms, is capable of producing 22.0kW power. As per the requirement of the OEMs, the engine can be offered in either vertical or tilted option. Moreover, if the need be, the engine can be incorporated with a Turbo Charger to increase power and torque.

The state-of-the-art manufacturing unit of Kohler is at Aurangabad, Maharashtra where engines for Diesel, Petrol and CNG variants of 3- and 4-wheelers are manufactured. Kohler offers its support for all the new vehicle projects to the Automotive OEMs. The comprehensive range offered by Kohler Engines in India has emerged as the foremost choice of the small commercial vehicle manufacturers.

The company strives to improve upon its current range and manufacture engines that offer better performance at lower running costs. It is working towards offering engines beyond 50kW, which meet the BS-IV/V emission norms and have minimal exhaust gas after-treatment. The company is analyzing the Indian market scenario to evaluate the viability of these introductions. It also plans to manufacture these engines in India in the near future to make them more affordable for local car manufacturers.

Kohler Co. acquired Lombardini in 2007 and currently, the global company Lombardini S.R.L is a part of the KOHLER Global Power Group. Lombardini is the third largest manufacturer of diesel engines up to 50 kW in the world and a leader in the respective market segment. Kohler provides a gamut of products, including furnishing, engines, generators as well as kitchen and bath fixtures. It owns five-diamond resorts and is also engaged in off-highway sectors, such as agricultural, construction, genset, industrial and marine.